Cashew Nut Shell Oil (CNSL): The Hidden Value Inside Cashew Processing

When people think of cashews, they think of the nut: roasted snacks, cashew butter, plant-based milk, and premium kernels graded W180, W240, W320, and beyond. But the nut is only part of the story. For processors and serious buyers, one of the most overlooked opportunities in the cashew value chain sits in plain sight: the shell. Specifically, the shell contains a valuable industrial feedstock called Cashew Nut Shell Liquid (CNSL), often referred to as cashew shell oil.

This article breaks down what CNSL is, what it can be used for, and why it matters for cashew-producing countries and processors aiming to scale profitability through value addition.

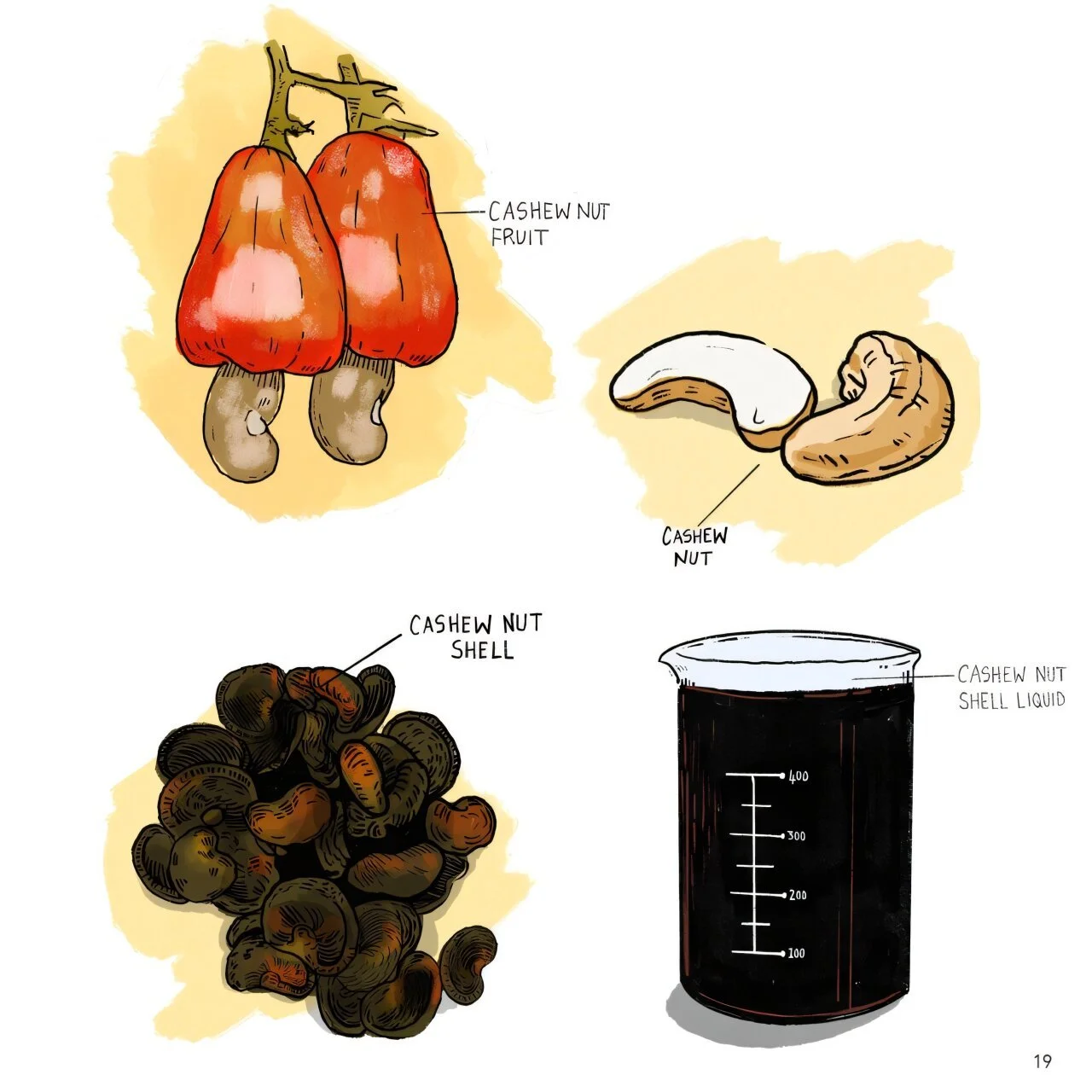

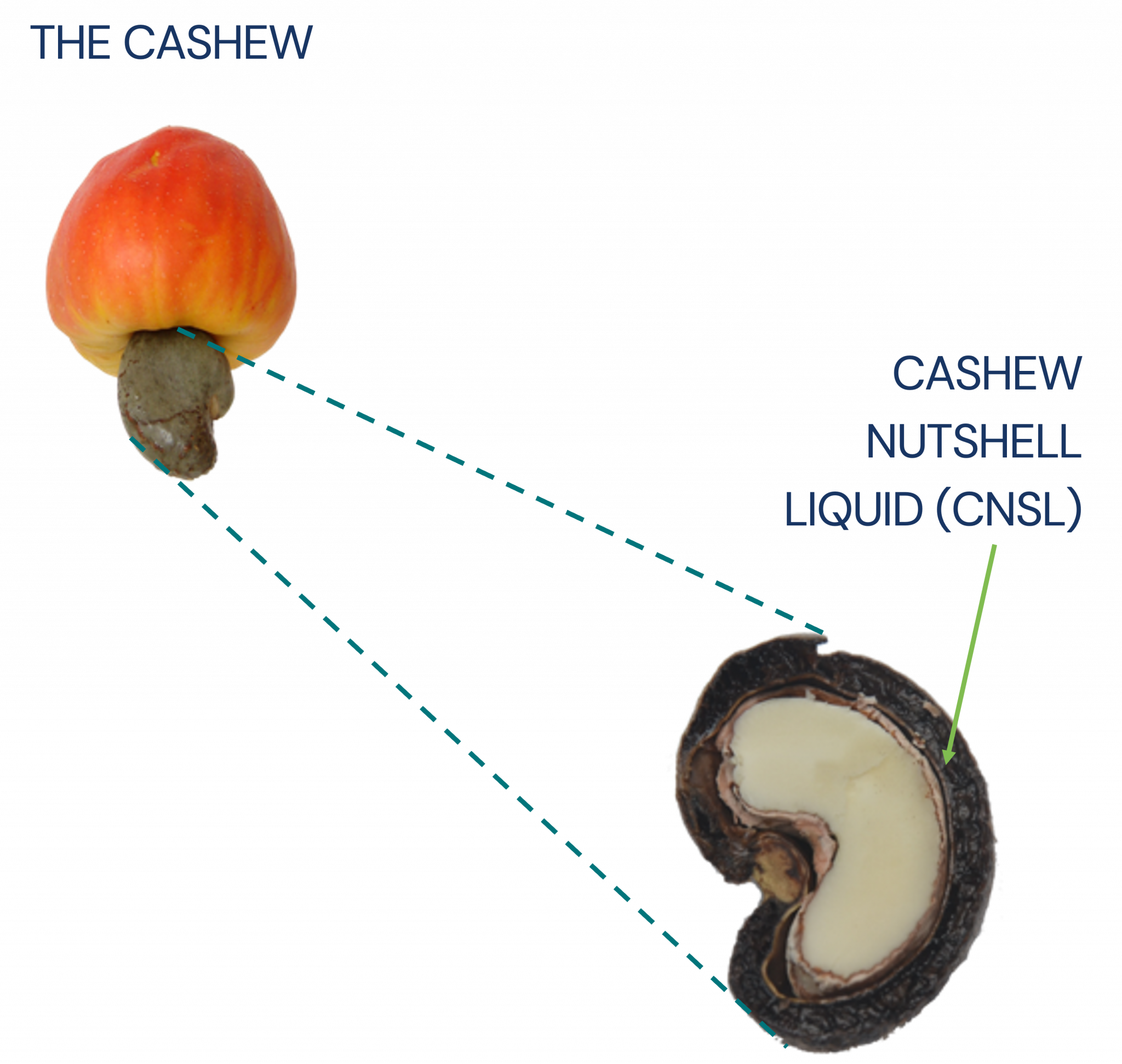

What is Cashew Nut Shell Liquid (CNSL)?

CNSL is a dark, viscous liquid found inside the honeycomb structure of the cashew nut shell. Chemically, it’s rich in natural phenolic compounds (notably cardanol and cardol), which are highly useful in manufacturing.

Important clarity:

CNSL is not an edible oil.

It’s an industrial raw material used to produce resins, coatings, friction materials, and speciality chemicals.

For processors, CNSL represents an additional revenue stream from what is often treated as waste.

Why CNSL Matters: Value Addition Beyond the Kernel

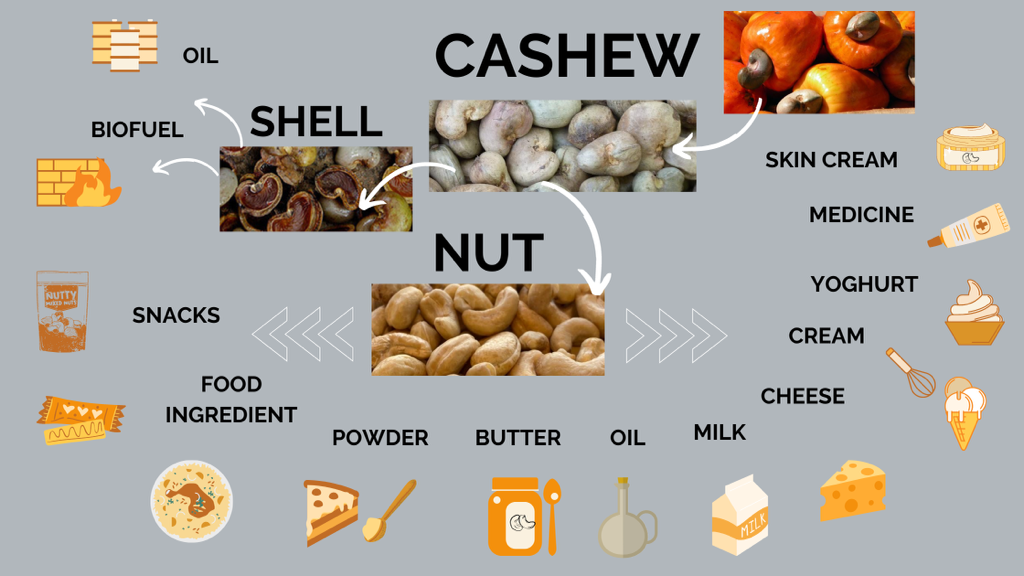

Cashew processing produces multiple outputs:

Kernels (food-grade product)

Testa/peel (sometimes used in energy applications)

Broken pieces (industrial food ingredients, confectionery, bakery)

Shells (the source of CNSL)

If shells are not monetized, they become a disposal problem.

If shells are processed properly, they become an input for higher-margin industrial markets.

In short: a processor can be selling kernels while also supplying chemical and industrial sectors. two very different markets, two revenue channels from the same crop.

What Can Be Made from Cashew Shell Oil?

CNSL and its derivatives are used widely because they offer strong performance and can be positioned as bio-based alternatives to petroleum-derived phenols in certain applications.

1) Friction Materials (Automotive + Industrial)

CNSL-based resins are valued for heat resistance and binding strength.

Brake pads

Clutch linings

Industrial friction blocks

2) Industrial Resins for Coatings and Paints

Used for chemical resistance, adhesion, and durability.

Anti-corrosion paints (marine, pipelines, steel structures)

Primers and industrial enamels

Protective tank and machinery coatings

3) Adhesives and Binders

CNSL resins can perform well in bonding applications.

Wood adhesives (plywood, particle board)

Rubber-to-metal bonding adhesives

Construction-grade adhesive systems

4) Rubber and Tyre Additives

CNSL derivatives are used as modifiers and processing aids.

Rubber compounding additives

Plasticizers and flexibilisers

Tyre production inputs

5) Laminates and Composites

Used in moulded and laminated products.

Industrial laminates

Fiberglass composites

Electrical and insulation components

6) Foams and Insulation Materials

Certain derivatives can be used in polymer systems.

Polyurethane foam modifiers

Insulation boards and specialty foams

7) Foundry and Industrial Applications

Foundry sand binders for casting cores

Abrasive and heat-resistant applications

8) Specialty Chemicals (Higher Processing Route)

With further refinement, CNSL can be converted into derivatives used in:

Surfactants and wetting agents

Emulsifiers

Dispersants for pigments and fillers

From Shell to Market: Where Processors Fit In

Processors can participate in the CNSL economy at different levels depending on capability and investment:

Level 1: Shell Supply (Entry Level)

Supply clean, dry shells to CNSL extractors or industrial users.

Lowest complexity, lowest margin.

Level 2: CNSL Extraction (High Potential)

Extract and sell crude CNSL in bulk.

Requires controlled processing, storage, and safety practices.

Better margins and buyer interest.

Level 3: Refining into Derivatives (Highest Value)

Convert CNSL into higher-value fractions like cardanol.

Typically done by specialised chemical processors.

Highest margin, but higher technical requirements.

Even Level 2 can significantly improve overall processing economics when managed well.

Handling & Safety: The Non-Negotiables

CNSL is a valuable product, but it must be handled correctly.

It can be a skin irritant/caustic.

Requires PPE, proper drums/liners, and safe storage

Buyers typically expect documentation such as:

MSDS/SDS (Safety Data Sheet)

Product specification sheet

Basic quality parameters and consistency

For processors, strong handling standards are not just “compliance”; they’re credibility.

Why This Creates Opportunity in Producing Countries

The biggest missed opportunity in many cashew origins is that countries export raw nuts and import industrial products later at higher prices.

CNSL is one of the clearest value-add paths because:

It’s already embedded in the processing chain

It converts “waste” into industrial revenue

It can attract buyers in manufacturing sectors beyond food

For investors and processors, CNSL is a practical step towards turning cashew into a multi-output industry, not just a kernel business.

Conclusion: Cashew is More Than a Nut

Cashew kernels will always be the flagship product, but the shell is not a leftover. It’s a raw material with industrial relevance.

For processors: CNSL can become a second income line.

For buyers: CNSL offers a bio-based chemical feedstock with proven use across friction, coatings, resins, rubber, and composites.

For the wider market: it’s a clear example of how value addition increases profitability and reduces waste.

If you’re involved in cashew processing or sourcing and want to explore shell utilization, CNSL extraction, or bulk supply structures, it’s worth mapping your position in the chain, and targeting the right end-users.